Many times have you seen a bat soar above your head? You might want to clap your eyes on it again. There are odds it could be a robot! Even if they are loaded with GPS pointers, it could still happily whoosh into a wall if that’s what the operator told it to do. These robots can now track objects and people from far above, avoiding obstacles.

SCARA robots are a perfect example of high precision and accuracy resulting in a technological breakthrough! It shows how test automation reduced manual works and made it more accurate and efficient!

SCARA robots serve as overlords and friendly companions performing mundane tasks. They provide perception sensors and allow people and robots to work together. When there evolve plentiful robot designs and machines in today’s marketplaces, there are reasons test automation helps in being cost-effective. Henceforth achieves higher throughput, precise and accurate work and henceforth attract venture capitalists.

Growing number of products and designs in robotic automation – How do you choose from the plenty?

Today’s robotic industry is getting more and more attuned towards gaining customer satisfaction than before. Test automation demands stringent quality and cost parameters. These have enforced a high development in automation. For this reason, test automation has seen changes in adopting good and cost-effective products in the recent years.

Can you ever imagine a plane without a pilot? Robotic Automation has gained a foothold in today’s industrial revolution. Learning the benefits are a boon. It does not stop venture capitalists from investing for the major following reasons :

- They can handle parts that are too small for the human eye and fingers to handle. They work according to how they are programmed.

- Robotic automation can save on resources as they do not require climate control or lighting, and help provide cleaner spaces.

- They are fast and flexible and find roles in small to high –sized operations.

- Repetitive tasks are handled well. As well as difficult, manual and risk contained tasks like having to work in high or low-temperature levels and in hazardous environments.

- Since it helps in achieving higher throughput, companies can vouch for larger contracts.

- Increased productivity gives the opportunity to expand on one’s skills and work on areas that need logical focus.

- Improved Quality Assurance. This helps in keeping the concentration levels of workers intact by avoiding repetitive mundane tasks.

- Cost-effectiveness – When set to work on repetitive tasks, it continues to work as told, even for 365 days a year. This is an obvious benefit for any manufacturer.

The Department of Labor statistics states that workers are maximizing their output capacity. Also, mention that automation helps manufacturers break that ceiling. Every manufacturer benefits from automation because it overcomes the difficulties associated with a manual workforce.

Eliminating the cost overheads in test automation

The three facts to consider which are associated with test automation costs are :

- Robotic Price Ranges

- Reconditioning

- Return Of Investments (ROI)

The real savings in costs associated with automation starts after the initial investment. Robotic automation eliminates a number of costs associated with labor. For instance, insurance, leave, accidents and holidays. Adding to this, the production numbers often increase with the efficiency of automated robots. They create a more consistent and quality oriented strategy. This does not waste time and saves manual effort. Thus, they help companies greatly reduce the overall costs of implementing automated testing.

A feedback matters along with the cost!

In the early 1980s, many robots were installed but were unsuccessful. The major reason being the initial cost associated with it. The situation is now rare. Many large companies produce hundreds of robots on to the market every year. Present day robots are much more robust. With better testing and automation came better path controls. Also other networking and technical advances.

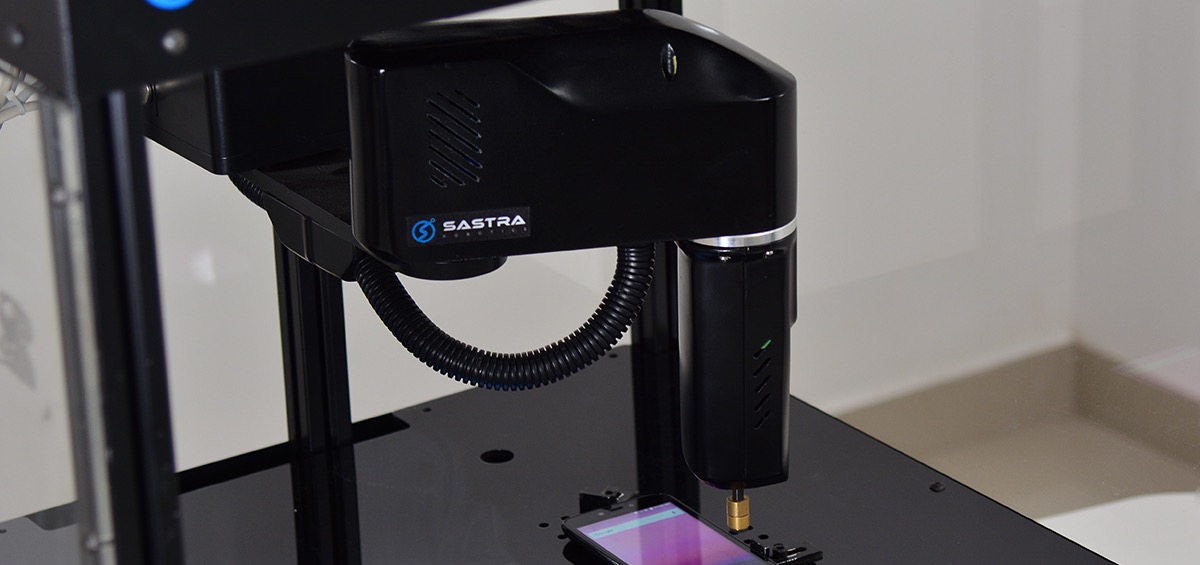

This is where the need for a good robotic automation that is both cost-effective and accurate comes into being. An exemplary would be the SCARA robot. It is named the SR-STR. It provides an accelerated testing solution for hardware and HMI products.

SR-STR to Transform the Future

The brisk performance was the best among the quality features of SR-STR. The previous versions took one-third of the time to complete test reports. SR-STR V5.0 has more additional features. It includes the Innovative – Force controlled stylus to ensure the safety of the DUT (Device Under Test).

The configurable force settings have a wholly new software calibration. It ensures accurate force application provided with variant sized tooltips. It provides three levels of full force control for all axis and the force control reduces the complexity of the system. This sensor-based solution offers 2 clicks per second. It has a display force-enabled. It consists of an active configurable stylus that performs a total quality check for displays. Its calibrated stylus tip position succeeds in calculating XY accuracy in a single point. It can be reconfigured for use in different products. It minimizes the tester idle-time. The SR-STR v5.0 is ideal to use with buttons, resistive touch panels and capacitive touchscreens.

This ensures a non-destructive testing, predictive maintenance and process optimization. Getting its implementation up and running can also be speedy even after umpteen number of test cycles. Moreover, despite the sophisticated nature of technology, the teaching process of the system is relatively simple and straightforward. It tests for different age groups of people including kids and adults. The conventional replaceable stylus tips imitate the touch profile of variant age groups. This includes all single finger gestures like taps and swaps, made possible with the TCP/IP APIs.

The SR-STR v5.0 includes a manipulator with the STM end effector and can test the touch screen and the buttons on the HMI panel. The optimized design it possesses for camera vision feedback system is another functional attraction. This camera vision feedback system can be added to the rig to enhance its capability. The test rig is adaptable to the type of the device to be tested. It can also be redesigned according to the need.

The SR-STR reduces the error rates associated with the execution. It has a 24×7 functionality. It thus enables the test engineers to develop better test procedures. The accelerated testing results in faster product development. This leads to increased output in the manufacturing plants. Hence it ensures efficient utilization of human resources and attracts more revenue per year.

The Real Cost Reducing Test Automation Solution with SCARA SR-STR v5.0

The real goal of automation testing is to reduce the cost and risk of failure by increasing test coverage. The SR-STR has proved accurate execution. Nevertheless, experience in test automation has proved that it takes between five and ten times faster. This is way faster than it takes to develop and debug an automated test. This is compared to when the execution is done manually.

The time to a market approach of SR-STR v5.0 has served its touch panel performance test system. The best cost-effective solution that ensures product quality and end of line testing. The basic robustness and longevity of SR-STR v5.0 have proved its efficiency in test automation. It is built keeping the customer’s easy integration in mind!

With the coming of SR-STR, Sastra Robotics has been more than committed to providing low-cost robotic solutions. This accommodates all the customer needs!

Let’s Work Together

Are you a technology business group, research institution or a robotics enthusiast? Contact us to avail the best solutions to suit your specific needs.