The robotic arm has an absolutely fascinating history, Leonardo da Vinci designed the first sophisticated robotic arm in 1495 with four degrees-of-freedom and an analog onboard controller supplying power and programmability. A sophisticated, self-propelled, mechanical device that was over 500 years ahead of its time. it was also fully programmable, with the ability to control its own motion and direction.

Fig. 1: Leonardo da Vinci’s front wheel drive, rack-and-pinion steering animated cart, (photos courtesy of Biblioteca Ambrosiana in Milan)

Unimate introduced its First Robotic Arm, invented by George Devol in 1962

The first industrial robotic arm was installed at the General Motors plant in Ternstedt, New Jersey, for automated die casting.

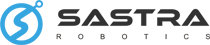

The robot arm resembles the human arm:

It has a base (torso) which enables it to rotate 180 degrees, connecting the arm (above the base) to the ‘shoulder’ joint ‘(manipulator) and also has rotational axes about its ‘elbow’ and ‘wrist’ joints. The hand(end effector) is connected to the wrist joint.

The Robotic Arm

Adaptation of robotic arms are along the lines of human anatomy and kinesiology

Standalone robotic arms are often classified as full robots.

Jointed robotic arms allow the arm to interact with the environment (product or workpiece) and have the following “4 parts”

1. Shoulder Joint

The shoulder joint the foundation for most modern robotic arms is the highest load-bearing joint in the arm and has the widest range of motion of any joint in the human body. The three degrees-of-freedom at the shoulder are yaw, pitch, and roll.

2. Elbow Joint

The elbow joint provides the wrist hand with:

- Extension

- Retraction

- Reach-around

- Angular reorientation

3. Wrist Joint

The wrist mechanisms developed for robotic arms were crucial in even the earliest prototypes. The wrist is the end-effector terminus of the robotic arm and it allows the arm to be manipulated in three-dimensional space. The robotic wrist is the ‘sine qua non’ for high-performance robotic arms.

4. Hand (End Effector)

The end effector, also commonly called End of Arm Tool, is a device or tool that’s connected to the end of a robot arm (where the hand /wrist would be ) and interacts with the environment (meaning the product or workpiece) to accomplish a specific task.

They are application specific, and many arms will fit multiple end effectors.

Two general categories of end effectors (including sprayers, grinders, welders, vacuums, inputs, and outputs ) viz.

1. Grippers that grasp and manipulate the work parts during the work cycle and

2. Tools that are used to perform processing operations on the work part like spot welding, arc welding, and spray painting

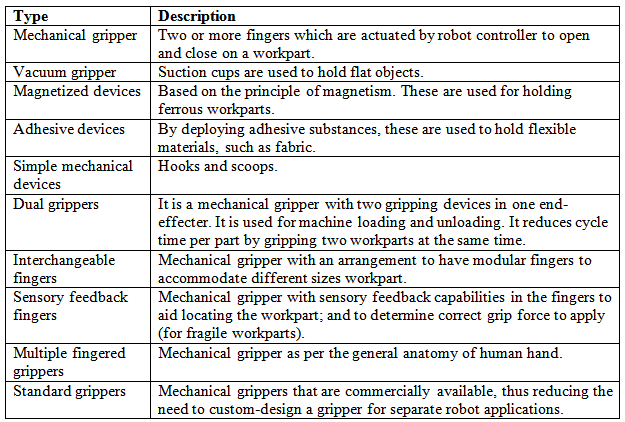

Various end-effectors, grippers are summarized in the table below:

In isolation, the robot arm itself is only responsible for positioning the end effector. With the robot arm, the shoulder, elbow, and wrist move and twist to position the end effector in the exact right spot. Each of these joints gives the robot another degree of freedom

Robotic Arms: The category of joints

Based on the category of joints (mechanical structure)-6 Major categories

Cartesian (also known as Gantry) robots

Have three joints that are coincident with the standard X-Y-Z Cartesian axes.

Have two parallel rotary joints to allow full movement throughout a plane, typically for pick-and-place work.

- Articulated Robots

Consist of three or more rotary joints and are used for complex assembly operations

Cylindrical arms, Spherical (polar) arms and Parallel robots comprise the other three.

(Left to Right) Gantry Robot, Articulated Robot, SCARA Robot

Robotic Arms: Definition by parameters

Number of Axes – Two axes are needed to reach any point in a plane. Three are required to reach a point in space. Roll, pitch, and yaw control are required for full control of the end manipulator.

Degrees of Freedom – Number of points a robot can be directionally controlled around. A human arm has seven degrees; articulated arms typically have up to 6.

Kinematics – Arrangement and types of joints (Cartesian, Cylindrical, Spherical, SCARA, Articulated, Parallel)

The others being: Working Envelope, Working Space, Payload, Speed, Acceleration, Accuracy, Repeatability, Motion Control, Power Source, Drive, Compliance.

Applications

Robotic arms are typically used in industry.

Repetitive autonomous robots perform one task repeatedly based upon predetermined movements and specifically located objects. If object orientation or position is unknown, arms are often paired with machine vision and artificial intelligence to identify the object and subsequently control the arm.

Sensors in Robotics:

There are generally two categories of sensors used for monitoring and control of robotic arms.

- Internal sensors for the various joints of the robot.

- External sensors for the operations of the robot

Hazardous Task Robots

Robotics and the military go hand in hand, especially where the US army is concerned. Towering, advanced robots like Big Dog and the humanoid Atlas developed by Boston Dynamics have been put to use in both training and real combat missions. By 2025, it’s thought that the US army could have more combat bots than human soldiers.

Assembly Line Robots

For industry and the automotive sector,

THT components are still integral parts of complex board assemblies. Connectors, capacitors, chokes or special components, often only a few of them per board, need to be manually placed on an in feed conveyor The Ersa ROBOPLACE to assume this monotonous, repetitive task for small to medium production volumes. THT components are still integral parts of complex board assemblies.

Robots for Inspection with Vision Systems

The use of advanced Vision Systems gives today’s manufacturers the ability to balance and address the importance of conformance, competitiveness and quality requirements.

To name a few: Part tracking, Defect Detection and Tolerance and Dimensional Inspection

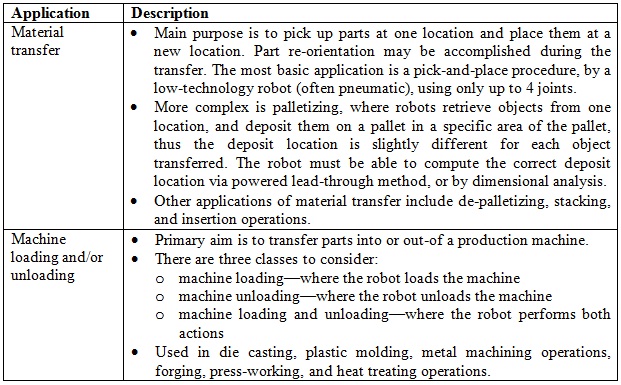

Material Handling Applications

Robots are predominantly used in three types of applications:

- Material handling

- Processing operations

- Assembly and inspection

- Material handling

Robots move parts between various locations by means of a gripper type end effector. Material handling activity can be subdivided into the material transfer and machine loading and/or unloading

Robots for Palletizing

Robotic Palletizing areas include automotive, medical, food and beverage, consumer packaged goods, warehousing, distribution, and fulfillment. These are flexible and reliable, maximize efficiency and reduce labor costs through order tracking, process speed, and workplace safety:

Processing Operations

In processing operations, the robot performs activities such as grinding, milling, etc. on the work part. The end effector is equipped with the specialized tool required for the respective process. Outlines the examples of various processing operations that deploy robots, see below table.

Robotic Material Handling Applications

Welding

Falcon delivers cost-effective solutions for dedicated and production welding systems which incorporate the latest welding technologies. Our team has the experience to supply new welding systems or retrofit used equipment, and even reconfigure current equipment to match compatibility of a new project. We provide stand-alone units, single/dual robotic flex cells, hybrid weld systems and complete tooling solutions:

- Ultrasonic Welding

- Spot and Friction Spot Welding

- MIG & TIG Welding

- Surgical robots

The first-ever FDA-approved hair transplant robot – Artas – is currently being used by about 20 surgeons in the U.S. and Canada, and was recently introduced in the UK and Korea. Removing individual hairs from the follicle (and a tiny bit of surrounding skin) is tedious for people to do but outsourcing this technically difficult task to a robot could make hair transplants cheaper and less painful.

Carnegie Mellon’s “Snakebot” slithers into your heart

CardioARM (nicknamed the “Snakebot”) is a tiny, 102-segment worm-like device designed by researchers at Carnegie Mellon University for performing minimally-invasive heart surgery. To do so, the robot enters the body (and then heart) through a 1 cm incision. The front end of the robot has tools to cut and cauterize depending on what sort of repairs need to be carried out. Without the trauma of creating a huge “zipper-scar” cut and cracking open a person’s rib cage, recovery times would be a fraction of the normal period.

Swallow hard: Propeller-bot is set to survey your insides

The ‘Royal College of Surgeons’ camera capsule is designed to explore the human digestive system. After swallowed, it “swims” to inspect an area of interest, driven by tiny propellers.

“NeuroArm” performs world’s first robotic brain surgery

Robotic brain surgery? Researchers at the University of Calgary and Canadian company MDA – who built the robotic arms for the Space Shuttles and the International Space Station – have teamed up to create a medical robot capable of performing brain surgery with a human operator.

NeuroArm has actually operated successfully on a human (who’s doing just fine now, by-the-way.)

Many variants of the robotic arm are on the way! Like the inflatable robotic arm constructed almost entirely of plastic elements: inflatable links, airbag actuators, and acrylonitrile butadiene styrene (ABS) joints. Controlled by a joystick with four degrees of freedom (4 DOF) to be used for healthcare applications in order to assist patients with eating their meals. The robotic arms mentioned above are just a glimpse of more to come!

Get Automated

Applications of robotic automation are already in place in every industry. The time is “Now”! Get started right away with our customized product and service-based solutions.

Embrace the future. Contact us to save your time and money to deliver a quality product.

Sources:

The National Center for Biotechnology Information

Boston Dynamics

Kurtzersa

New Scientist

Neuro Arm